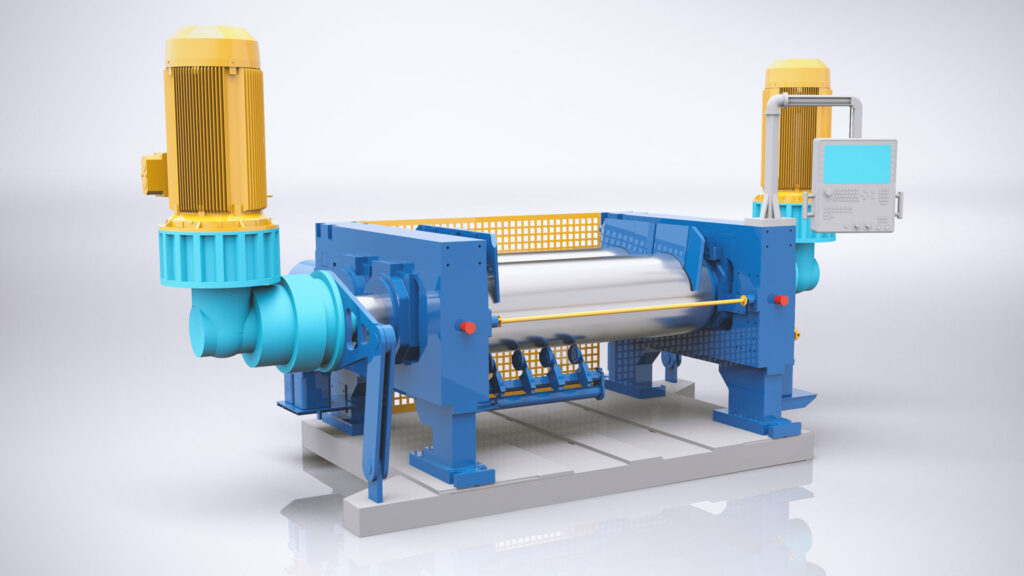

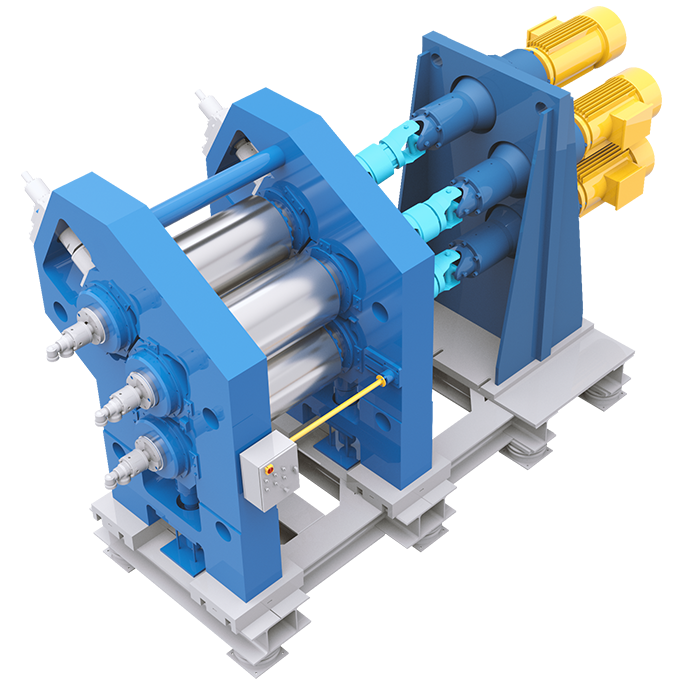

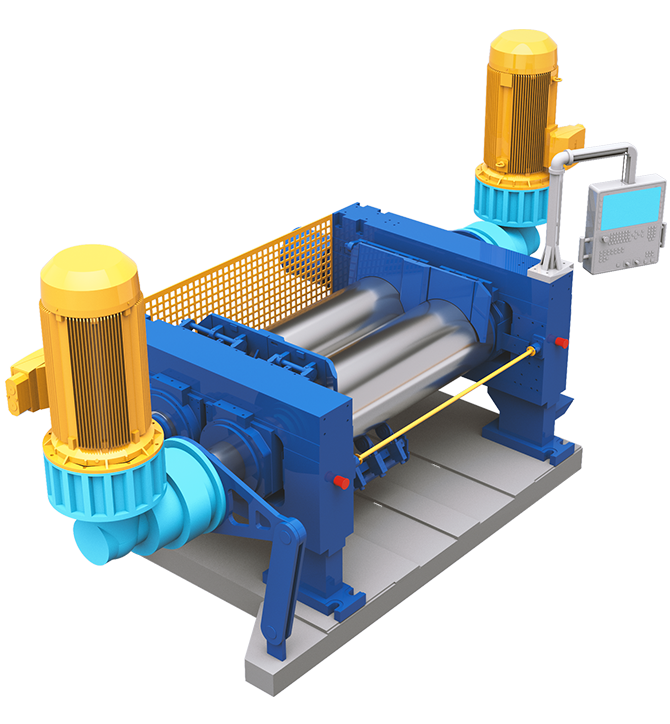

Open Rolls Mill

Repiquet has always been one of the forerunners of technical improvements. In the specific field of mixing, the opens mills represent today the synthesis of the most recent improvements based on many years of experience.

The complete range of rolling mills and mixers covers all the needs of the rubber, plastics and other chemical industries, such as powder, dye and pigment factories etc…

Our mixers are designed to provide the user with a very high production capacity of high quality mixtures.

The performance of a mixing workshop depends on the characteristics of its equipment, but also on its robustness, maintenance time and use flexibility. Our mixers meet these different criteria.

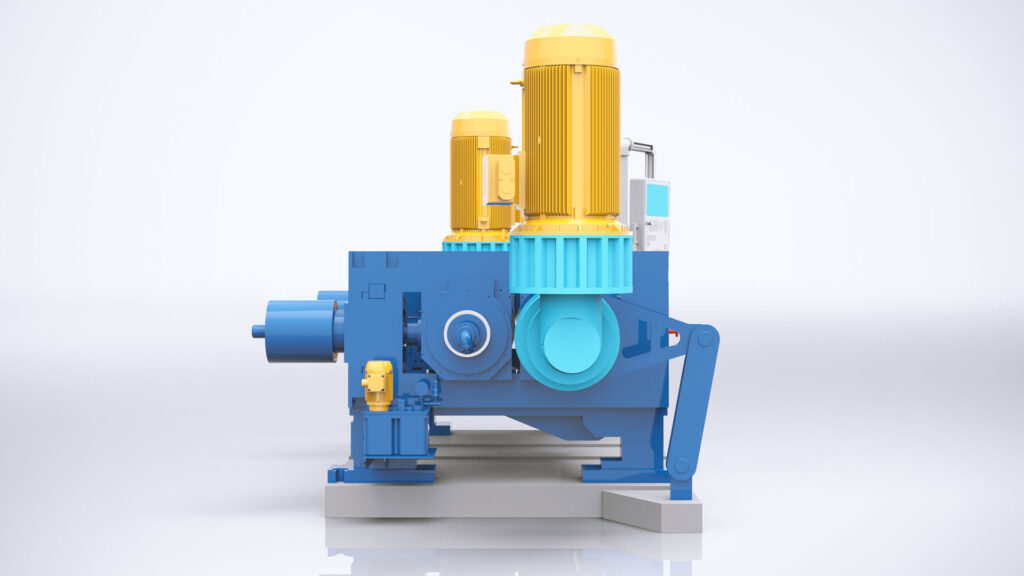

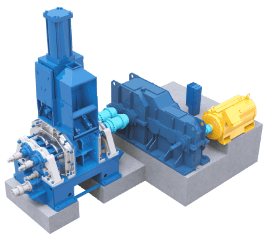

Helical gear speed reducer

Gear hobbing is carried out on a very high-precision machine. Lubrication is provided by an oil bath or by a motor-pump unit. The shafts are mounted on bearings. The connection to the motor is ensured by a semi-elastic coupling. The direct connection to the rear cylinder of the mixer is made by a chain coupling sleeve.

Rear cylinder

The drive is provided by direct engagement of the rear cylinder and the ratio gears.

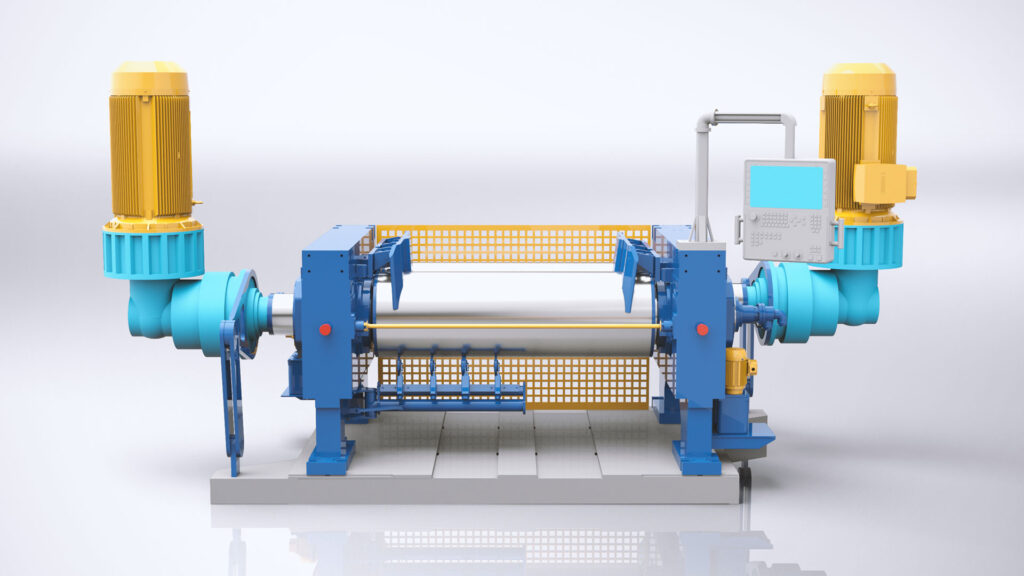

Cylinders

Cylinders made of hardened cast iron cast in a die-casting mould, have a surface hardness of 450/480 Brinell units. The inner chamber is machined for efficient and uniform heating or cooling. As an option, the cylinders can be executed with drilled peripheral channels under the hardened cast iron layer to accelerate heat exchange.

Cylinder spacing adjustment, by screw and nut, is carried out manually in the case of infrequent changes of setting.

A safety capsule against accidental overload is placed between the adjusting screws and the bearings of the front cylinder.

Roll bearings

Roll bearings are made of high-strength cast iron with bronze bushings. They are lubricated by a closed-circuit oil flow with flow control by means of a motor pump unit.

A safety device on the returns eliminates any risk of seizure.

Frames

The frames are made of cut steel or high-strength cast iron. The stapling of the caps to the frames and the dimensioning of these highly ribbed parts give them a particularly high degree of robustness.

Option

Many mixers are also equipped with cut steel bearings mounted on roller bearings.

Monobloc mounting on anti-vibration pads

Thanks to their mounting on anti-vibration pads, these units do not transmit any vibrations to neighboring machines or constructions; incidents usually caused by vibrations on the mechanical parts of the mixer are eliminated.

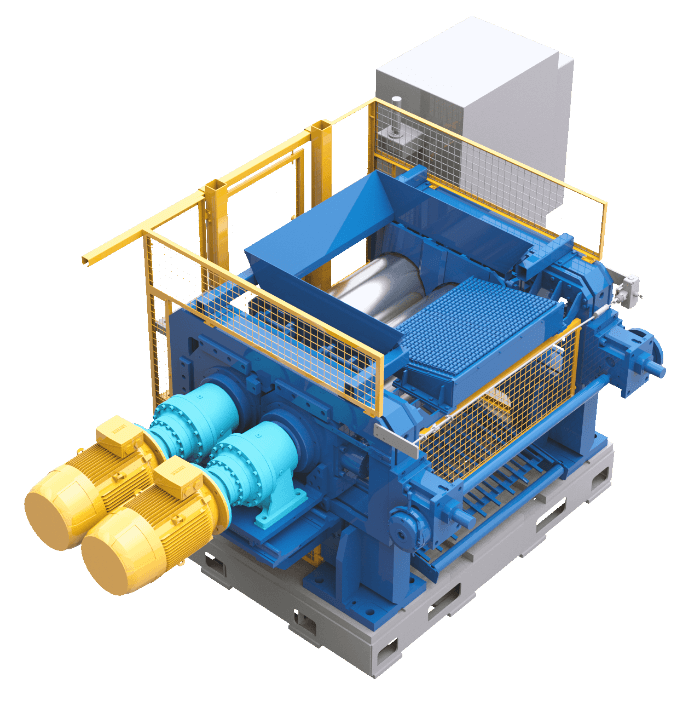

Safety stop

The design of the “McNEIL REPIQUET” mixers guarantees maximum safety. The safety stop of the machine is obtained by a simple action of the operator on 2 bars located at the front and at the back of the mixer.

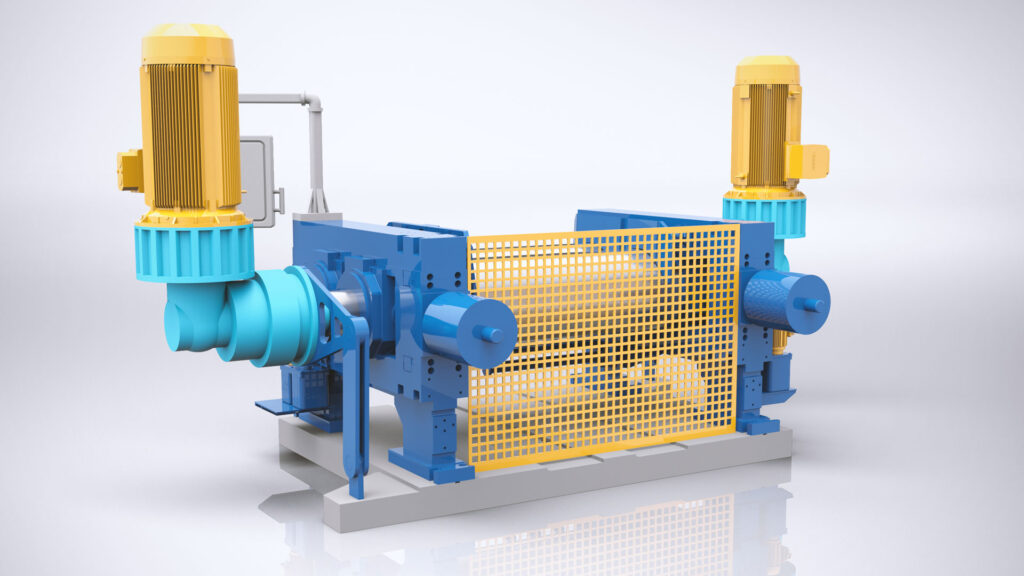

Accessories and additional devices

The material guide reserves are usually fixed on the cylinder bearings.

As an option, it is possible to equip the “McNEIL REPIQUET” mixers with liftable or automatically shifting reserves.

For special cases, our mixers can be equipped, on request, with a drip tray under the cylinders, a central reserve, a rammer, a transfer device, fixed or removable cutting systems, automatic re-engaging blender, scrapers etc.

The combination of such accessories with remote controls, supplemented by infeed and outfeed conveyors, can lead to automatic operation by PLC without direct manual intervention.

Special devices

In the case of automated systems, cylinder spacing can be achieved either by means of gear motor units (1 or 2 speeds) or by a hydraulic cylinder system incorporated in the frame heads with linear sensor positioning.

Numerous installation possibilities

Depending on the layout and the number of mixers to be installed in a mixing plant, we offer different solutions:

– Individual control by cylindrical or cylindro-conical reducer with motor placed on the right or on the left of the operator,

– Group control for two mixers with a central gearbox

– Control of two, three, four or six mixers by semi-subterranean transmission

For some industrial or laboratory applications, each cylinder can be individually controlled by a set of cardan shafts, pinion cage and single or variable speed motor. The mixer can also be equipped with two gear harnesses to provide equal speed or friction between cylinders.

A complete range of specialized mixers

Followers, breakers, homogenizers, feeders, mills, refiners, rolling mills…

The various processes for producing mixtures require the use of mixers adapted to specific functions. To meet this need, we offer a complete range derived from standard open mills. The following illustrates some of the uses of these devices and their possibilities within the framework of a complete mixing workshop for plastics or rubber.

Follow-on mixer

At the outlet of the internal mixer, the follower mixer allows to plate the product. In addition, we provide the user with conveyors, crushers and cutting devices.

Warming-breaker mixer

These tools carry out, in the best conditions, the heating and mixing of the rubber previously stored, before the passage on calender or plodder. Breaker-heaters are equipped with grooved cylinders.

Homogenizing mixer

This mixer is frequently equipped with a Blender device which allows a better homogenization of the product in a shorter time and eliminates manual interventions of gum re-engagement.

Feeder mixer

The mixer feeder is usually placed after a homogenizer in rubber workshops, or directly at the outlet of the internal mixer in the case of plastics. It is equipped with belt cutting devices for feeding a plodder, a calender or a granulator.

Mixer mill

Mills or crackers are equipped with fluted rolls. The design of the rolls and the power of the crusher guarantee an excellent granulation of the vulcanised rubber waste (even from large parts such as tyres).

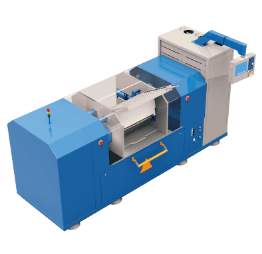

Mixer-refiner

Refiners are involved in the manufacture of special products such as powders with a rigorous fineness of grain or rubber mixtures with very high physical characteristics. The various units are available in various sizes. The specific characteristics of each are shown in the table summarising the range. Our range of twin roll tools also includes special application rolling mills for various chemical industries.

Powder rolling mills

Weapon or hunting powders are processed and put into plates on twin-roll mills equipped with remote controls and exceptional safety devices.

General characteristics of the range of open mills

| Cylinder dimensions Open Mills ø x L mm | Usual speeds in meters/mn rear cylinder | Power (KW) | Overall dimensions in mm | Approx. weight without motor in kg | ||

| Length | Width | Height | ||||

| 200 x 400 | 15 | 11 | 2200 | 1600 | 4700 | 4700 |

| 350 x 700 | 19 | 22 | 3500 | 1600 | 9000 | 9000 |

| 400 x 1000 | 22 | 37 | 3900 | 1600 | 12000 | 12000 |

| 500 x 1300 | 24 | 51 | 4300 | 1800 | 16000 | 16000 |

| 550 x 1500 | 36 | 110 | 5400 | 1800 | 30000 | 30000 |

| 600 x 1800 | 36 | 125 | 5700 | 1800 | 31000 | 31000 |

| 665 x 2100 | 38 | 185 | 6500 | 2000 | 39000 | 39000 |

| 700 x 2200 | 38 | 260 | 6800 | 2000 | 45000 | 45000 |

| Réchauffeurs-breakers 665 x 2100 | 38 | 220 | 6500 | 2000 | 39000 | 39000 |

| Crushers 550 x 1000 | 24 | 130 | 5000 | 2800 | 27000 | 27000 |

| Refiners 600/500 x 800 | 38 | 110 | 4700 | 2800 | 26000 | 26000 |

The speeds of the front cylinder vary according to the nature of the product to be mixed and the function of the mixer. The models shown above are standard models and this range is not exhaustive.