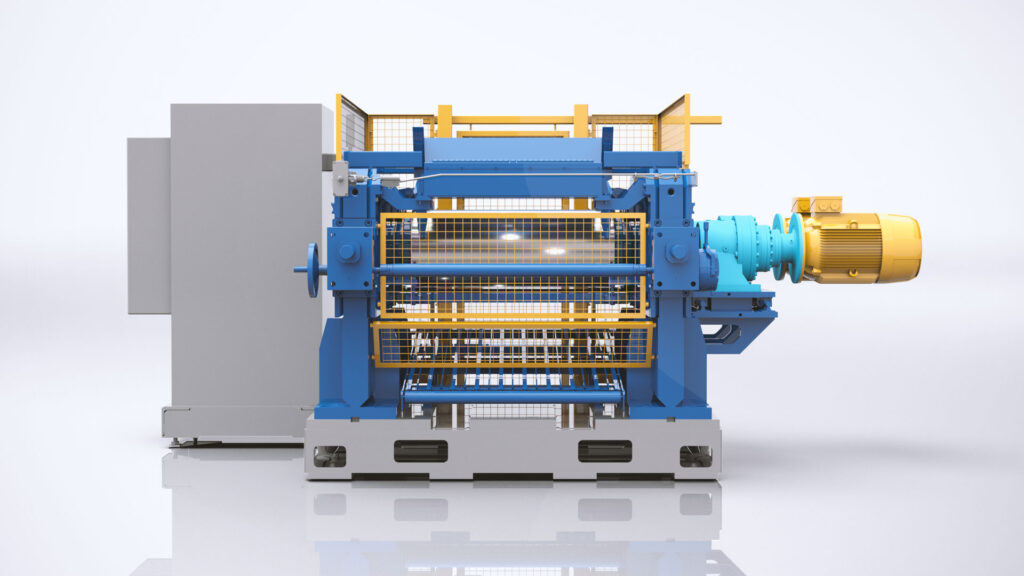

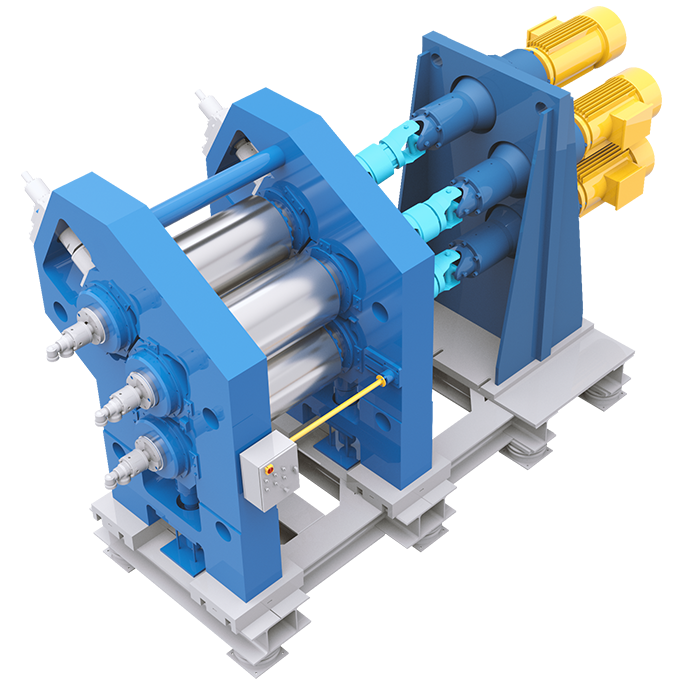

Push Out Mill

- For Scrap Material reprocessing through outlet sheets maximum 1meter width or extended possiilities

- 390x1000mm compliant with 25 kg of compound / batch

- Optimized Footprint allowing 100% rubber residues reprocessing

- Stand-Alone basis

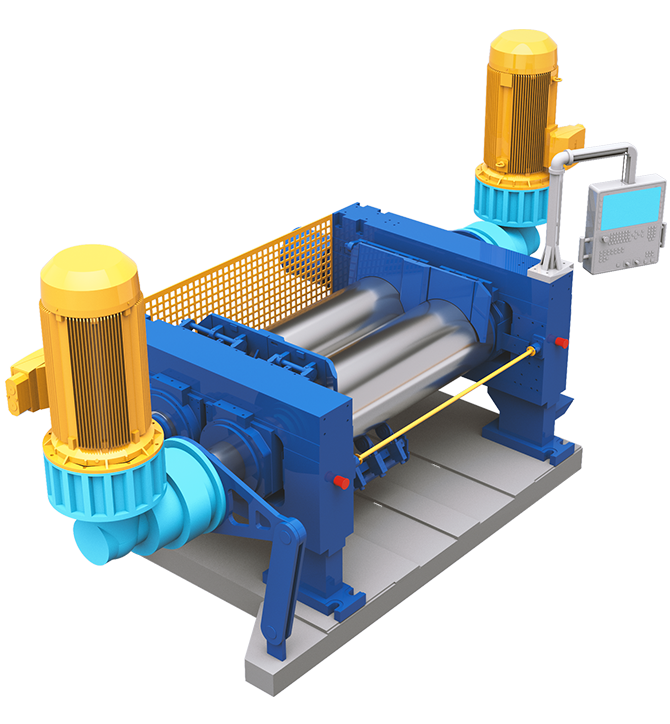

Standard Features:

- Manual Nip Adjustment : 5-50mm

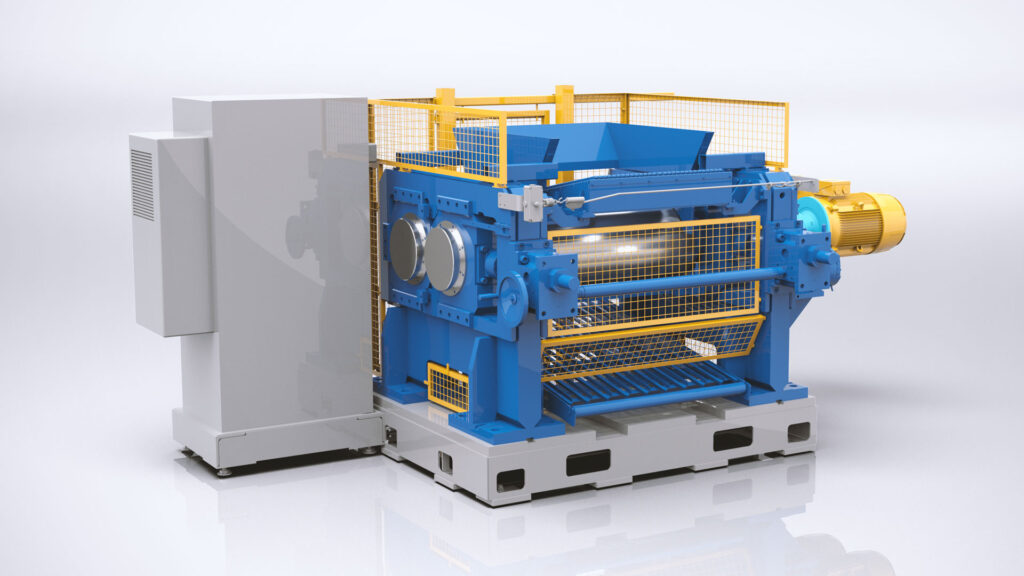

- Controlled Closed Automatic Area – Scrapers device integrated for anti-sticking action

- Outlet Belt Conveyor for Ergonomy improvement

- Feeding sliding board

- Rockwell Touch Screen Control

- Controlled Safety compliant with all regulation

- Maintenance compliant with Goodyear CTI-006-02-00003

- Fixed Stock Guides – Easy cleaning Operation

- Automated Lubrication Unit

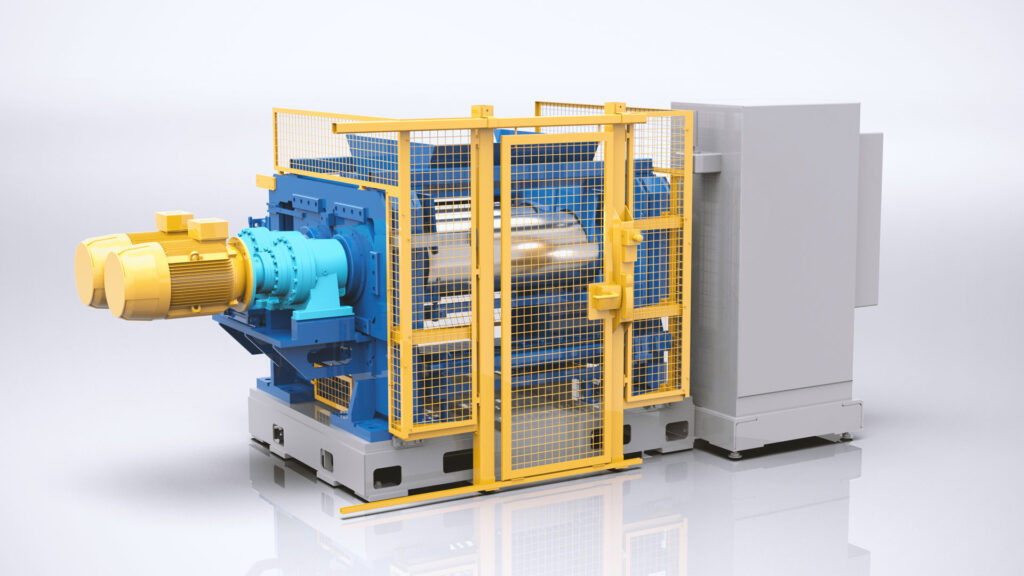

Available Options :

- Integrated TCU for both Rolls

- Hydraulic Nip Adjustment : 5-50mm

- Open Area with Safety front bar for dedicated processing

- Movable Stock Guides

- Very Easy Maintenance

- Plug and Play Installation

- Compact Design

- Compliant with future productions (hardener compounds)

- Environment-compliant through ECO approach design

- Energy-Saving compliant through Inverter control

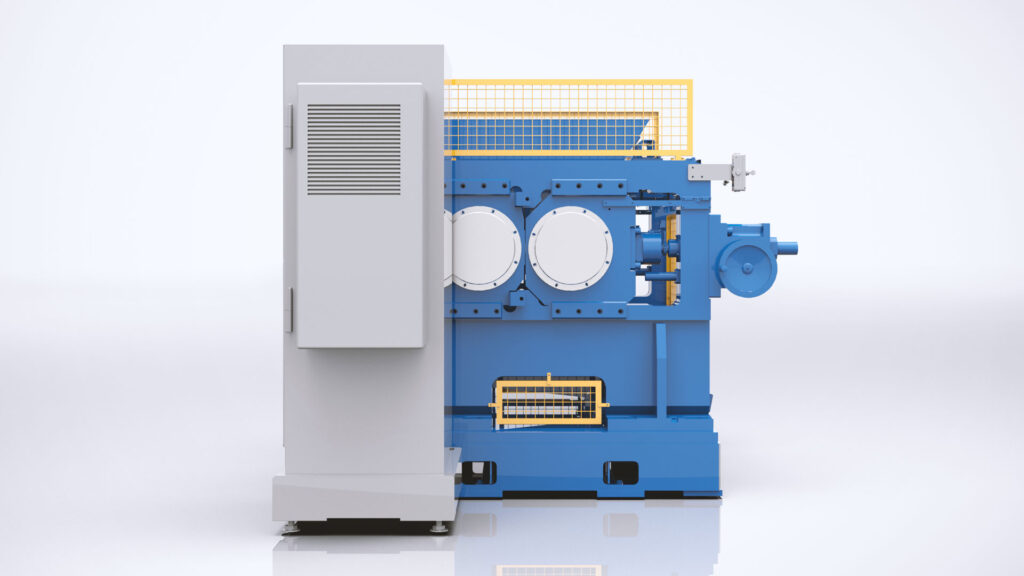

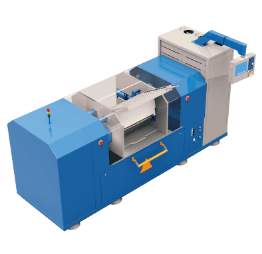

Spécifications techniques

| ROLLS DIMENSIONS mm | MOBILE FRONT ROLL SPEED M/Min | REAR ROLL SPEED M/Min | POWER KW | LENGTH (mm) | WIDTH (mm) | HEIGHT (mm) | APPROX WEIGHT (Kg) |

| 390 x 1000 | 9 – 15 | 13 | 2 x 18.5 | 3000 | 1800 | 1900 | 10500 |

Improvement/Modification available :

- Reduction of Roll Speed vs Optimized Power if speed importance is requested

- 90° Gearbox Mounting if saving more space is requested